Empowering Manufacturers through Decentralized Production

Embracing the Circular Economy

Introduction

The concept of a circular economy has gained significant traction in recent years as a sustainable and environmentally friendly alternative to the traditional linear economy. In a linear economy, resources are extracted, used, and disposed of, leading to significant waste and environmental degradation. In contrast, a circular economy aims to minimize waste and maximize the value of resources by promoting the reuse, refurbishment, and recycling of products and materials. An intriguing aspect of the circular economy is its potential to drive the decentralization of production processes, transforming the way manufacturers operate. In this blog post, we will explore how the circular economy is facilitating the decentralization of production and the benefits this transition can offer to manufacturers.

The Circular Economy and Decentralized Production

At its core, the circular economy envisions a system where products, components, and materials are continuously cycled through various stages of use, remanufacturing, and recycling. This approach inherently challenges the traditional model of centralized production, which often relies on large-scale manufacturing plants and global supply chains. Decentralized production, on the other hand, involves moving production processes closer to the point of consumption, reducing transportation distances, and fostering local production networks.

The circular economy aligns seamlessly with the principles of decentralized production by emphasizing the following key aspects:

Localized Production: Decentralized production encourages the establishment of smaller, local production units that cater to regional demands. Circular economy practices, such as remanufacturing and refurbishment, can be more effectively integrated into local production setups, reducing the need for extensive transportation of goods.

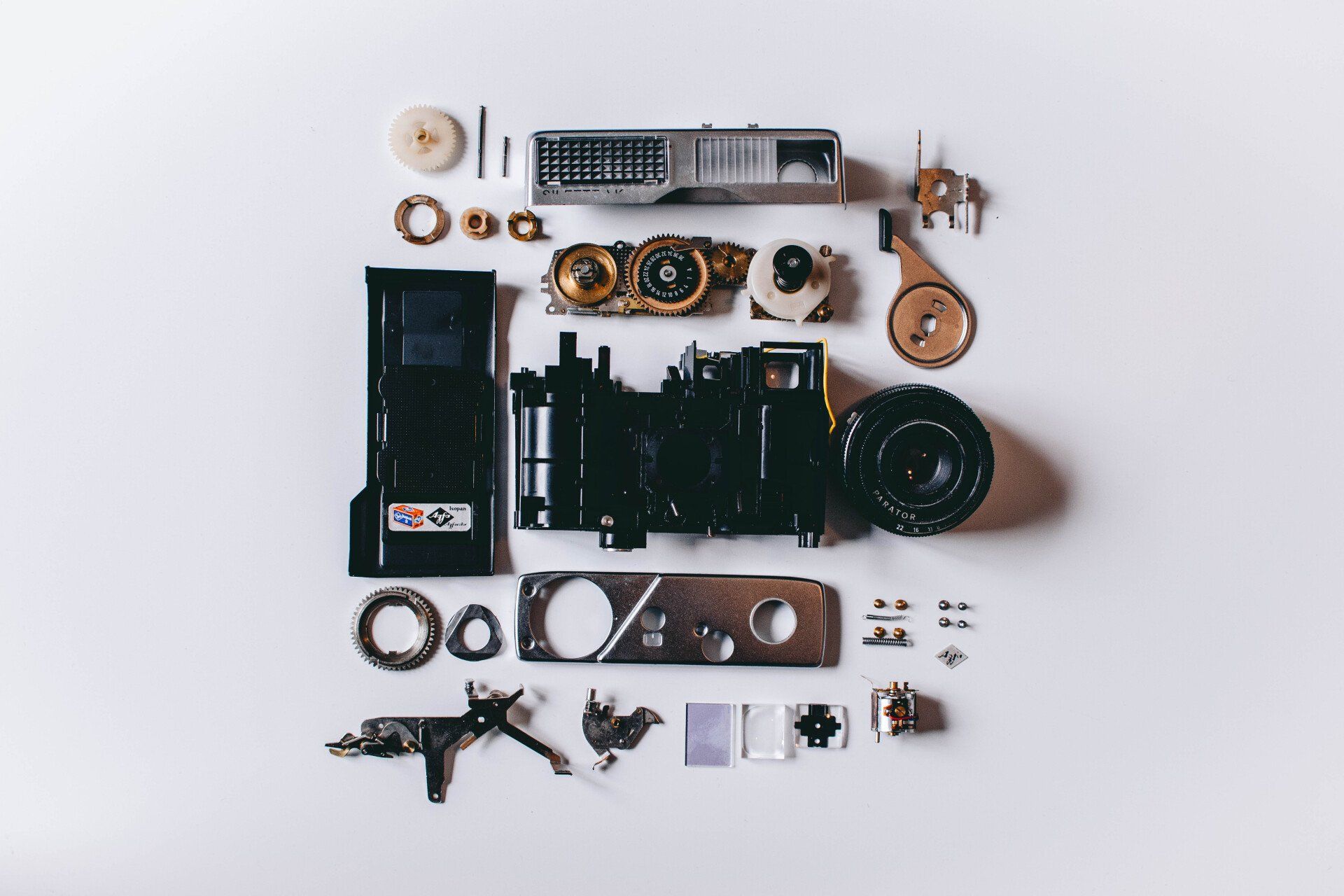

Resource Efficiency: Manufacturers embracing circular economy practices are driven to design products with longevity, easy repair, and disassembly in mind. These principles align with the goals of decentralized production, as products designed for circularity can be more efficiently disassembled and remanufactured on a smaller scale.

Reduced Environmental Impact: The circular economy's emphasis on reducing waste and minimizing resource consumption contributes to a lower overall environmental footprint. When combined with decentralized production, which reduces the need for long-distance transportation, this can lead to significant energy savings and emissions reductions.

Resilient Supply Chains: Circular economy practices often necessitate a diverse range of local suppliers and partners. This diversification inherently builds resilience into the supply chain, making it less susceptible to disruptions caused by global events or supply chain bottlenecks.

Benefits for Manufacturers

The synergy between the circular economy and decentralized production offers manufacturers several noteworthy benefits:

Cost Savings: While transitioning to circular economy practices may require initial investments in design and infrastructure, decentralized production can lead to long-term cost savings. Localized production reduces transportation costs and minimizes the risks associated with global supply chain disruptions.

Innovation and Flexibility: Decentralized production encourages manufacturers to be more responsive to local market needs. This agility promotes innovation and the ability to adapt products quickly, ultimately enhancing competitiveness.

Job Creation: Embracing a circular economy and decentralized production can foster the creation of new jobs at the local level, from production and remanufacturing to repair and recycling.

Improved Reputation: Consumers are increasingly demanding sustainable and ethically produced goods. Manufacturers that adopt circular economy practices and decentralized production can enhance their brand reputation and attract environmentally conscious consumers.

Conclusion

The marriage of the circular economy and decentralized production represents a powerful transformation in the manufacturing industry. As more manufacturers recognize the potential benefits of this paradigm shift, we can expect to see a transition toward more localized and sustainable production processes. By embracing circular economy principles and decentralizing production, manufacturers can reduce their environmental impact, cut costs, drive innovation, and contribute to the creation of a more resilient and sustainable global economy.